Automation solutions implemented

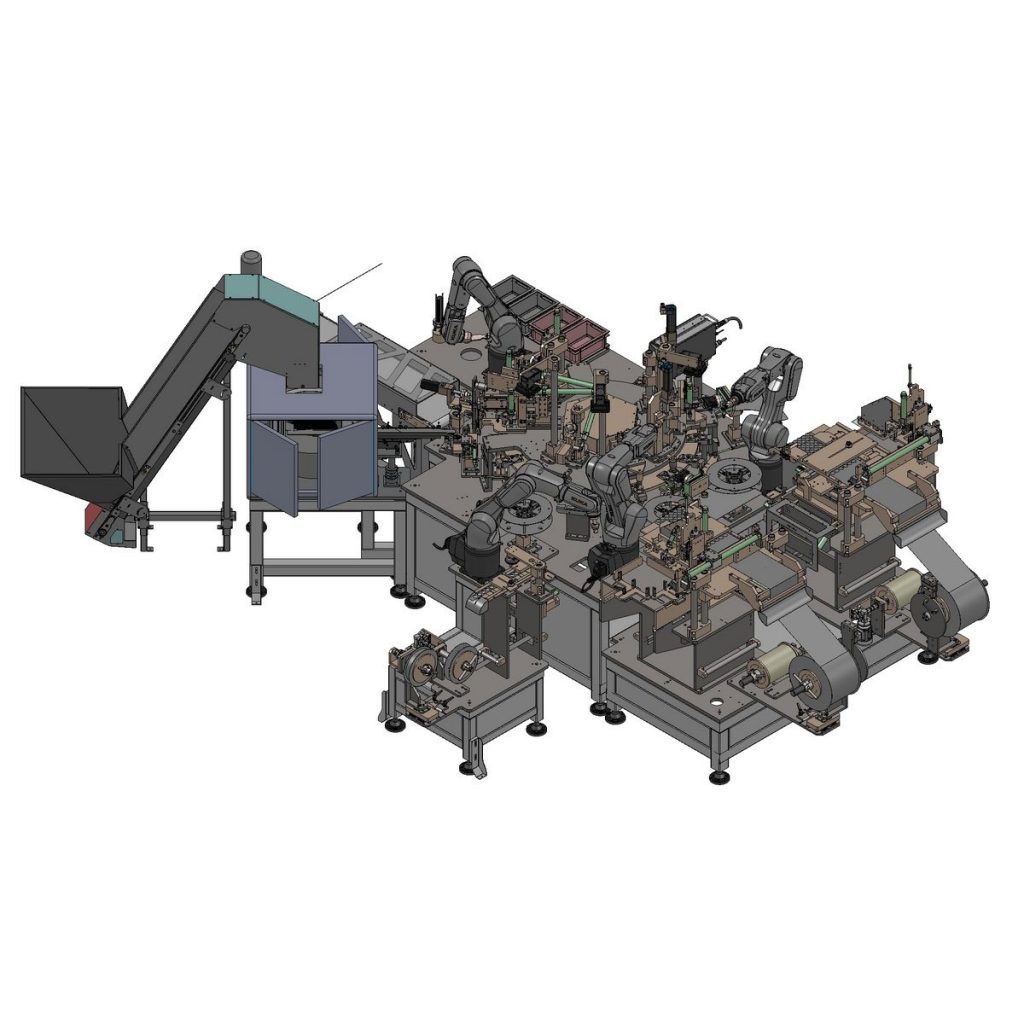

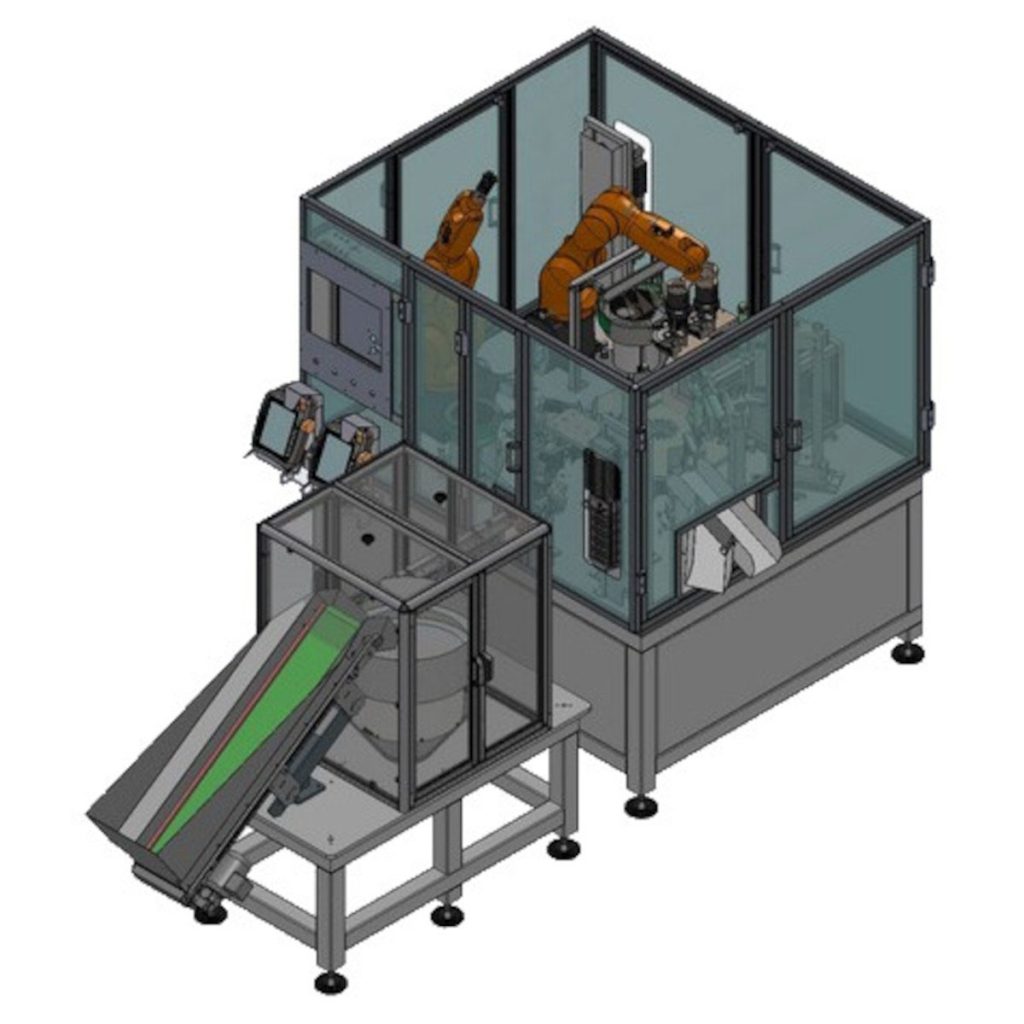

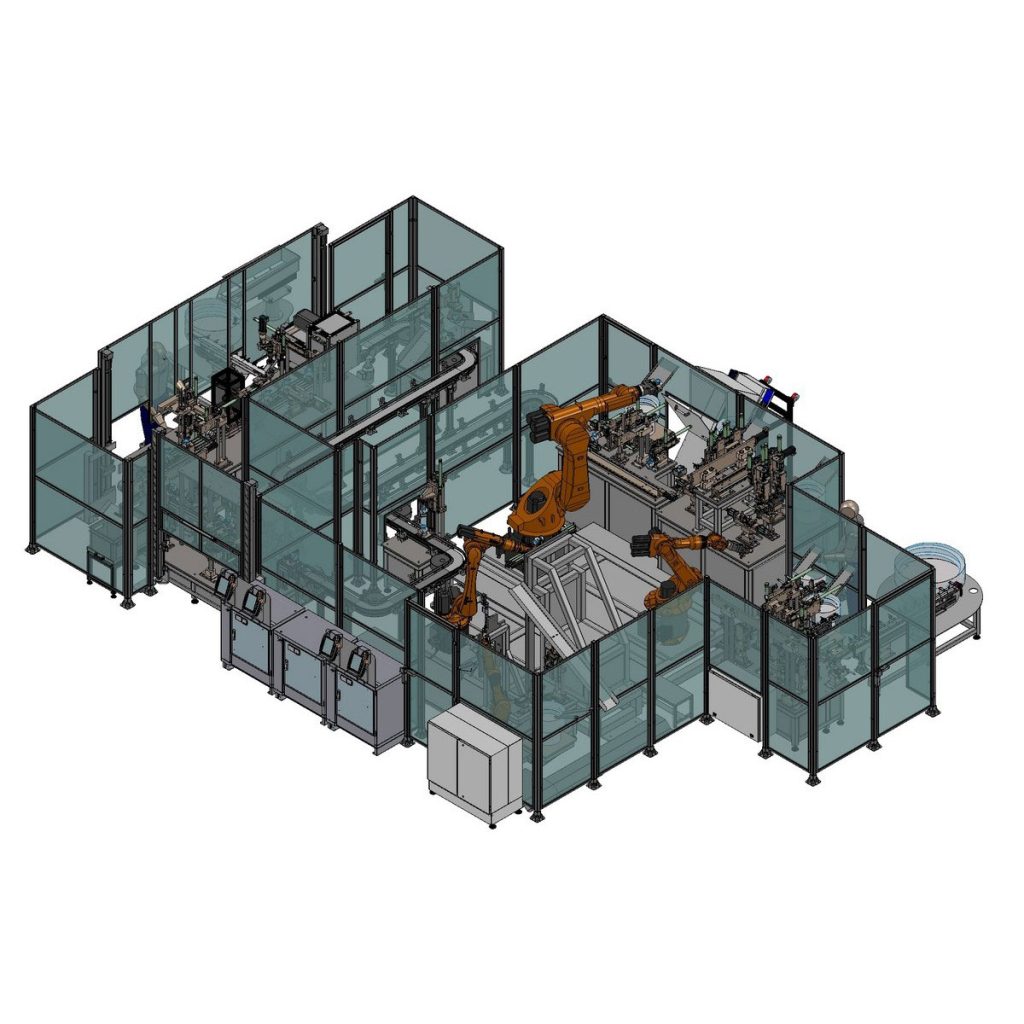

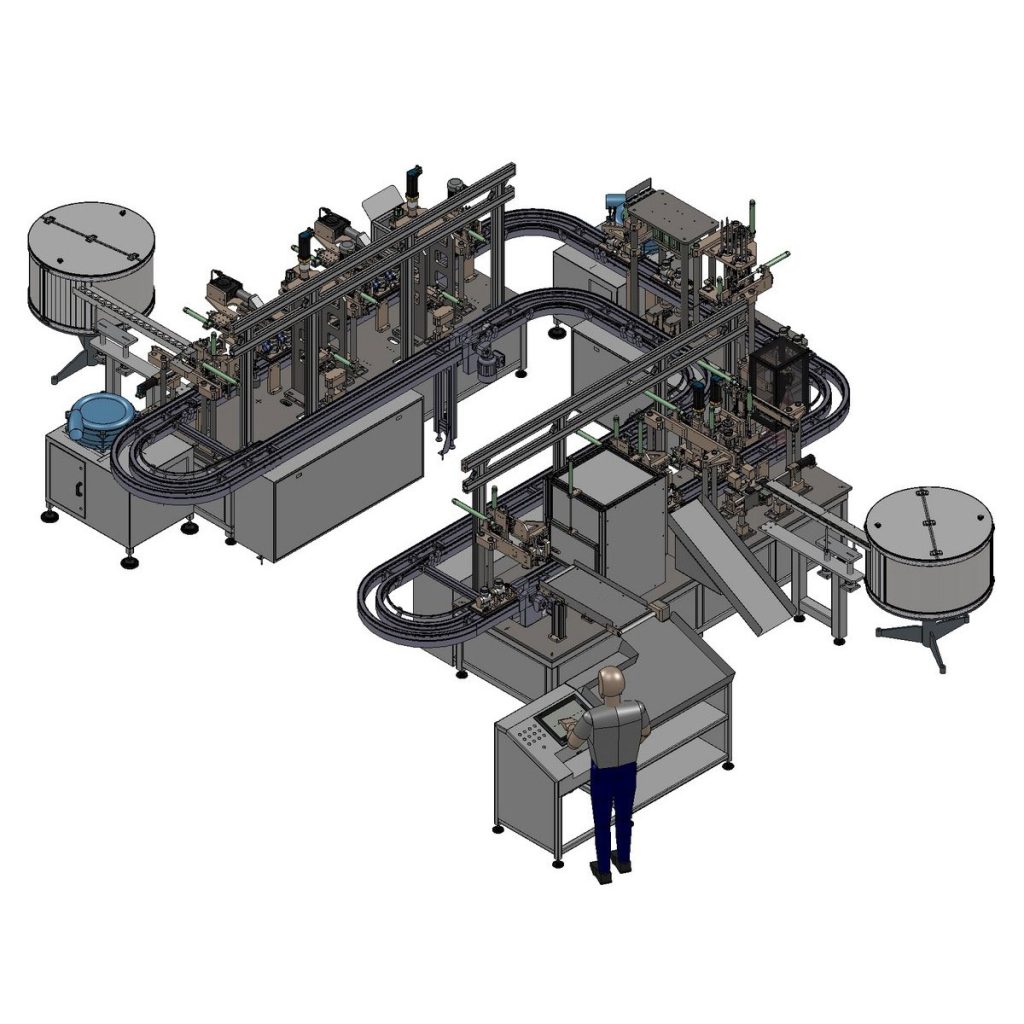

Thanks to the use of the anthropomorphic robot, parts of very complex shapes can be created using the same philosophy of numerical control, but with the addition of incredible flexibility in terms of working field, speed, and customization of the system based on the actual needs of the customer.

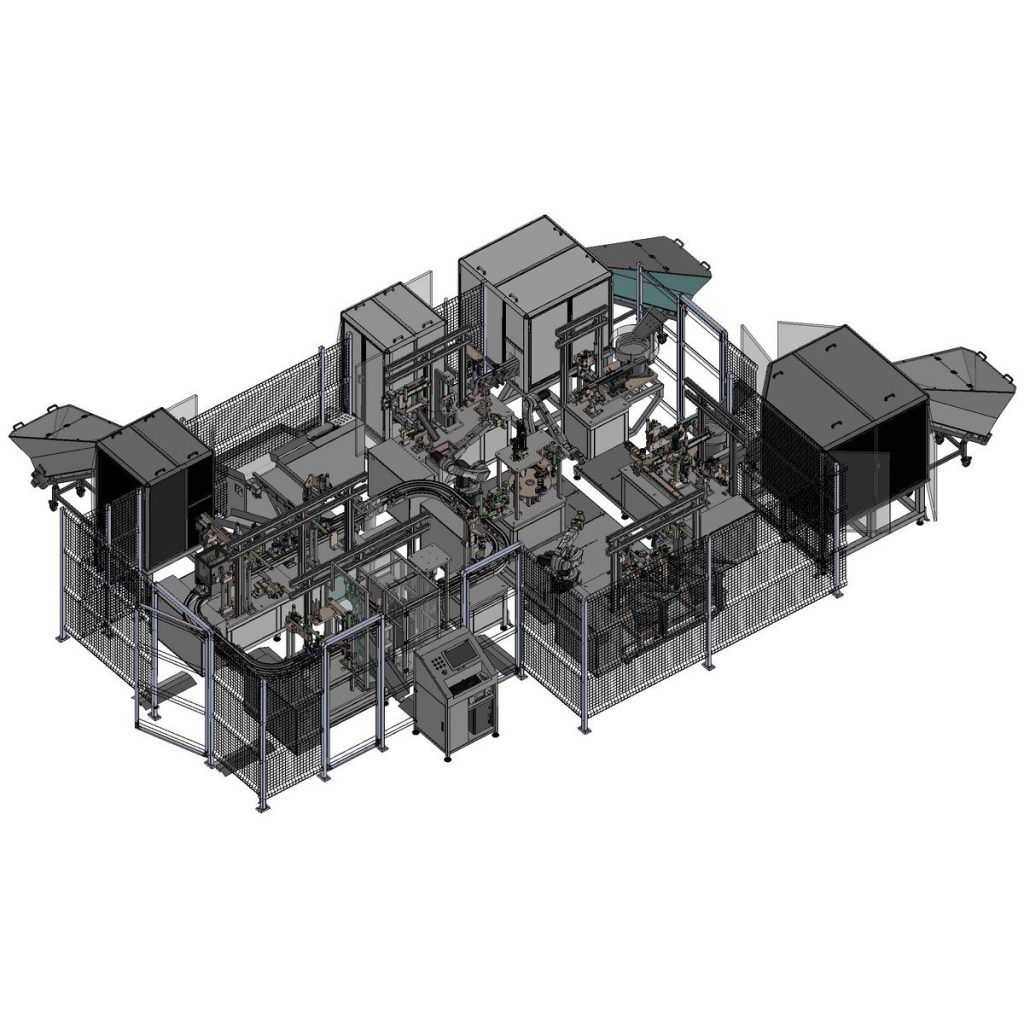

The possible configurations are almost unlimited, as the island can truly be tailored to the customer like a suit.

It is successfully used in the field of prototyping, production, creation of bulky parts, non-standard production, artistic objects, windows, ceiling and wall coverings, gadgets, promotional material, etc.

The system comes with offline post-processor simulation software that can convert APT or ISO files into robot language.

The following are available upon request:

- probe arm for programming points and paths

- laser scanner for creating three-dimensional models from samples or prototypes

- 5-axis Cam for generating tool paths

You can customize:

- wrist reach and robot range of action

- electrospindle or other end-effector with tool change capability

- tool magazine with automatic change

- automatic tool presetting

- rotary axis with rotary table

- linear axis for robot movement to expand the working range

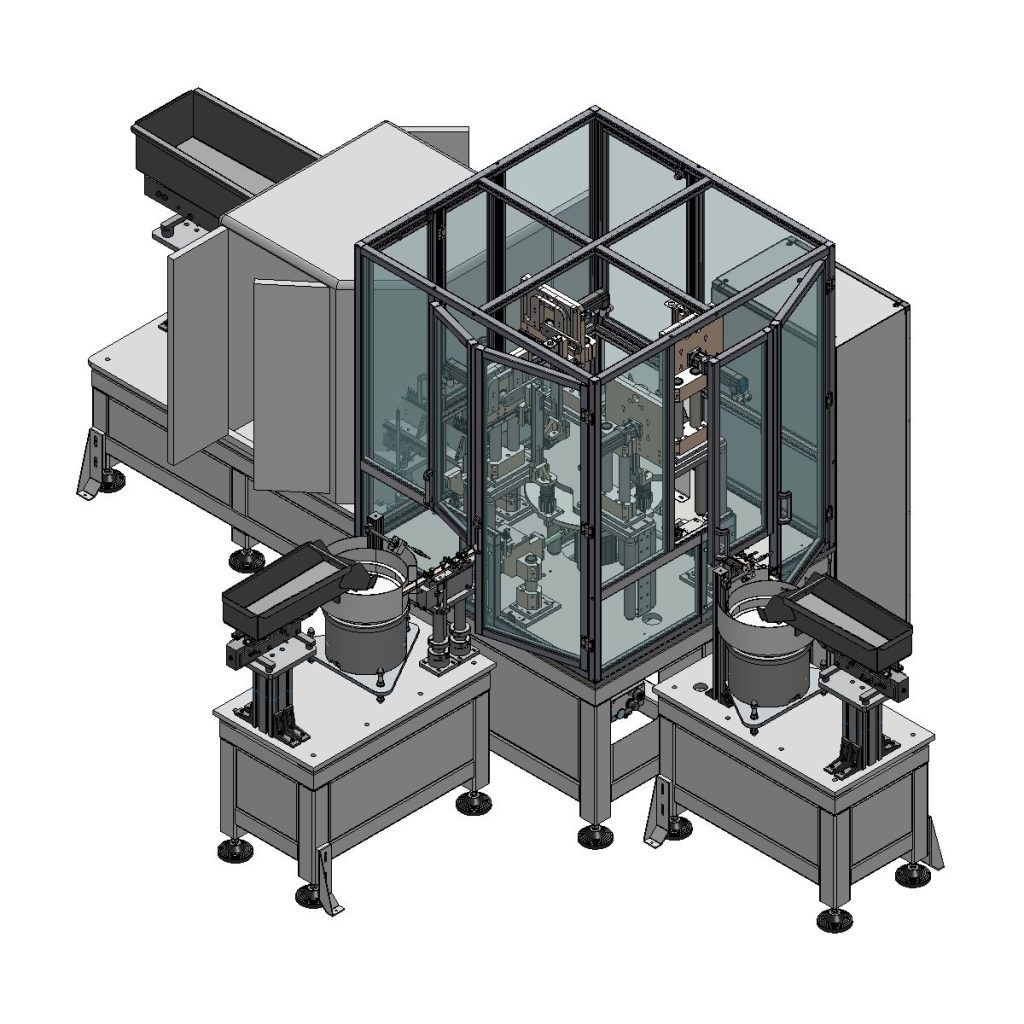

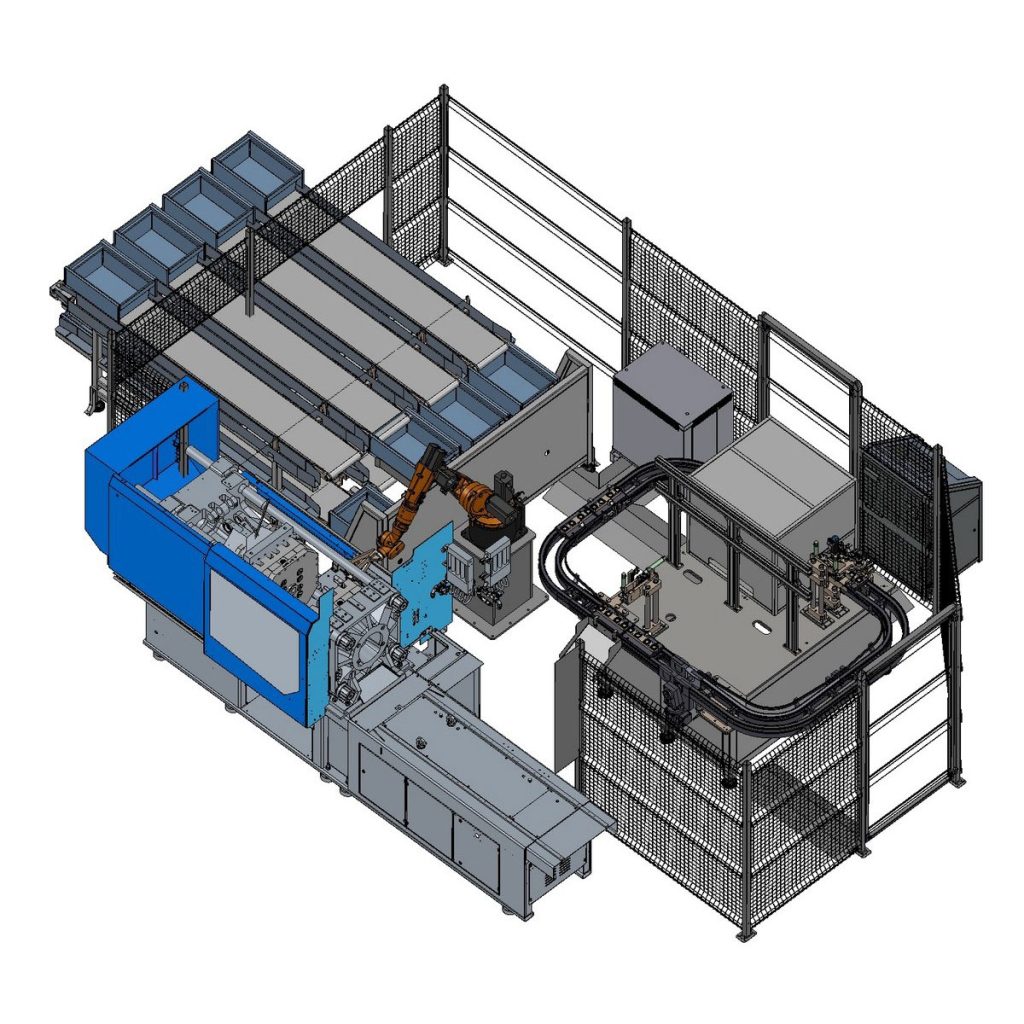

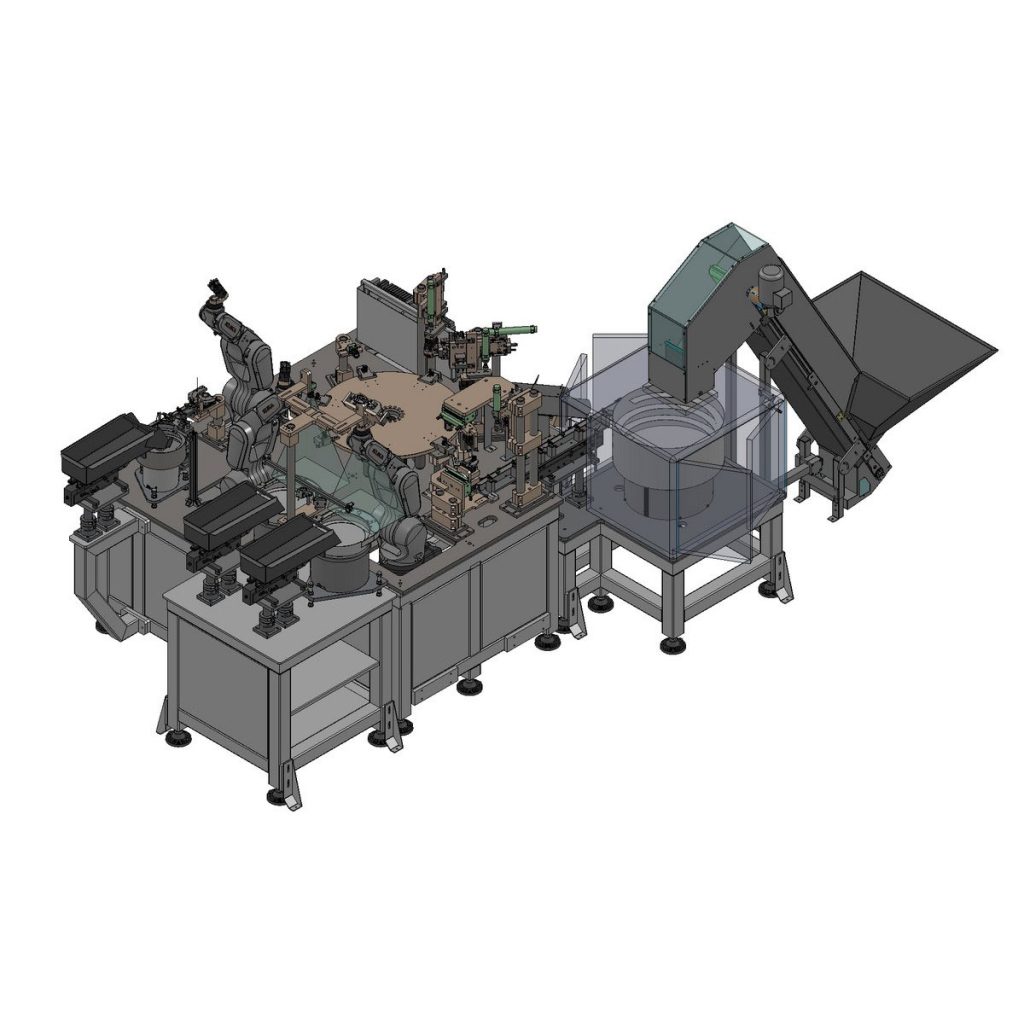

The classic configuration of the island includes a robot of a size appropriate to the object to be produced, a rotary table interpolated with the 6 axes of the robot, an electrospindle, and a tool magazine.

The advantages compared to traditional machines are:

- complete turnkey system

- flexibility

- wide customization capacity based on actual needs

- speed

- cost-effectiveness

- ease of programming and use

- large and easily expandable work area

- possibility of working with additional interpolated axes

Configuration example

Technical data

- 1600 mm range of action

- robot positioning repeatability: +/- 0.1 mm

- programming via commercial 5-axis CAD-CAM, directly in ISO or APT code

- 4 Kw electrospindle with ISO30 cone

- 17-position tool magazine

- optional mechanical presetting